Silicon Steel

Primary CRGO Silicon Electrical Coils

The widespread adoption of silicon steel coils in electrical equipment can be attributed to several inherent advantages that set them apart from conventional materials. Some of the key advantages i...

DESCRIPTION

The widespread adoption of silicon steel coils in electrical equipment can be attributed to several inherent advantages that set them apart from conventional materials. Some of the key advantages include:

a) High Magnetic Permeability: Silicon steel exhibits high magnetic permeability, meaning it can carry magnetic flux lines with ease. This results in improved transformer efficiency and reduced energy losses.

b) Low Core Losses: The low hysteresis and eddy current losses of silicon steel coils translate to minimal energy dissipation, ensuring efficient power utilization.

c) Temperature Stability: Silicon steel remains stable even under varying temperatures, making it a reliable choice for electrical applications that encounter temperature fluctuations.

d) Cost-effectiveness: The cost-effectiveness of silicon steel coils makes them commercially viable for mass production, further driving their widespread adoption.

e) Environmental Benefits: With increased emphasis on sustainability and eco-friendly technologies, the energy-efficient nature of silicon steel coils aligns perfectly with global efforts to reduce carbon footprints and conserve resources.

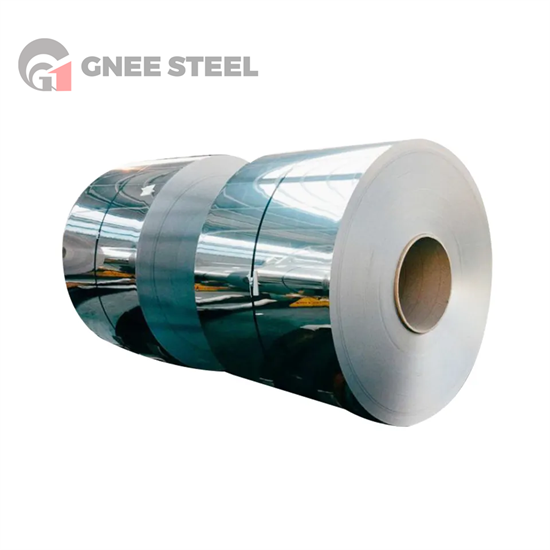

| Thickness Available | 0.23-0.35mm |

| Width Available | less than 1200mm |

| Inside Diameter | 508mm+-10 |

| Coating Available | Insulation coating |

| Width Tolerence | less than 2mm |

| Flatness | less than 2% |

| Edge Camber within 2m | less than 1.5mm |

| Features | 1. Low core loss

2. High Permeability 3. Small difference in size 4. Suit for punching and cutting 5. Good adhesiveness |