Silicon Steel

GNEE 27zh100 high quality cold rolled non-grain oriented electric CRNGO silicon steel

The difference between oriented silicon steel and non-oriented silicon steel Non-oriented silicon steel: ferrosilicon alloy with very low carbon content. In the deformed and annealed steel sheet, ...

DESCRIPTION

The difference between oriented silicon steel and non-oriented silicon steel

Non-oriented silicon steel: ferrosilicon alloy with very low carbon content. In the deformed and annealed steel sheet, its grains are distributed randomly. The silicon content of the alloy is 1.5% to 3.0%, or the sum of the silicon and aluminum content is 1.8% to 4.0%. The products are usually cold-rolled plates or strips, which are mainly used to manufacture motors and generators.

Oriented silicon steel: It has strong directionality, the lowest iron loss value in the rolling direction, the highest magnetic permeability, and a higher magnetic induction value under a certain magnetization field. The silicon content of oriented silicon steel is about 3%. It also requires a low content of oxide inclusions in the steel and must contain certain inhibitors (MnS, A1N).

Products Description:

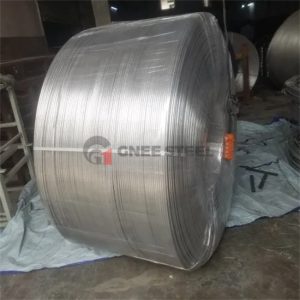

| Product name | GNEE 27zh100 high quality cold rolled non-grain oriented electric CRNGO silicon steel |

| Grade | DD51D+ZM,S350GD+ZM, DX51D+ZM |

| Standard | AISI,ASTM,BS,DIN,JIS ,GB,JIS A653 |

| Thickness | 0.4mm-6.0mm as customer’s demand |

| Width | 900mm-1500mm |

| Coil weight | 5-14 Tons |

| Zinc coating | 40-600/M2 |

| Place of Origin | China |

Packing and transportation:

- Delivery time: 7-15 days after receipt of deposit

- Packaging: standard bevel end of bundle

- Delivery: Professional freight forwarder, faster delivery

- Shipping: by sea or air, by international express