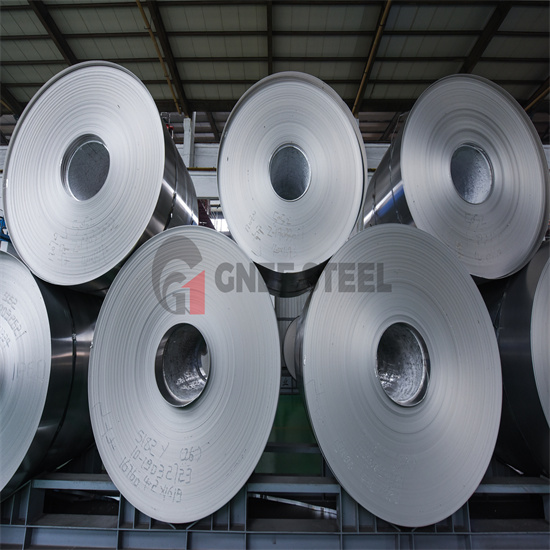

Silicon Steel

CRGO 27q120 0.23mm Thickness M4 Grain Oriented Non-Oriented Electrical Steel

The cold-rolling process used to produce CRNO steel involves passing the steel through a series of rollers at room temperature. This process not only reduces the thickness of the steel, but also re...

DESCRIPTION

The cold-rolling process used to produce CRNO steel involves passing the steel through a series of rollers at room temperature. This process not only reduces the thickness of the steel, but also refines the grain structure, leading to improved magnetic properties. After the cold-rolling process, the steel is typically annealed to further improve its magnetic properties.

Products Description:

| Product Name | Cold Rolled Non-Oriented Silicon Steel |

| Standard | M310, M350, M470, M600, M800, M1300 |

| Thickness | 0.35mm-0.5mm |

| Width | 10mm-1250mm |

| Length | Coil,Sheet Or As Required |

| Technique | Cold Rolled,Hot Rolled |

| Surface Treatment | Coated |

| Application | Widely used in transformers, generators, various household motors and micro-motors, etc. |

| Special Use | Silicon Steel |

| Sample | For Free (Within 10 KG) |

FAQ:

1.Q: How is the payment terms?

A: Normally T/T 30% in advance and T/T 70% before shipment.

2.Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

3.Q: How does your factory do regarding quality control?

A: We always pay great attention to quality control from the very beginning and every product was tested piece by piece before delivery.