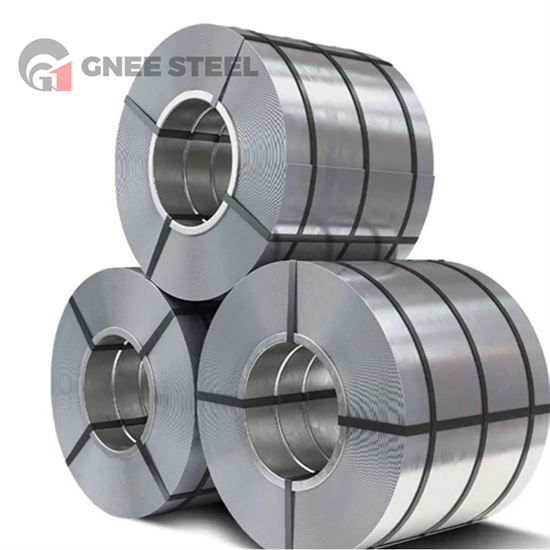

Silicon Steel

CRGO Electrical Silicon Steel Coil For Three Phase Transform

The manufacturing process of silicon steel coils involves several critical steps. Firstly, the steel is carefully selected and subjected to precise annealing to optimize its magnetic properties. Ne...

DESCRIPTION

The manufacturing process of silicon steel coils involves several critical steps. Firstly, the steel is carefully selected and subjected to precise annealing to optimize its magnetic properties. Next, the steel is rolled into thin sheets, typically ranging from 0.1 to 0.5 millimeters in thickness. These thin sheets are then wound into coils, forming the core of electrical transformers and other electromagnetic devices.Silicon steel coils offer numerous advantages that make them the preferred choice for electrical applications. Their low core losses minimize energy wastage and improve the overall efficiency of electrical equipment. Additionally, their high magnetic permeability allows for the design of compact and lightweight transformers, reducing space requirements and enhancing portability.

| Certificate | ISO9001 |

| Color | Customized Color |

| Package | Standard Seaworth Packing |

| MOQ | 1 Ton |

| Port | Tianjin\Qingdao\Shanghai |

| Sample | Avaliable |

| PAYMENT TERM | L/C T/T (30% Deposit) |

Q:Why should I choose your products?

A:Our products are high quality and low price.

Q:The logo and the color can be customized?

A:Yes, we welcome you to sample custom.

Q:Any other good service your company can provide?

A:Yes,we can provide good after-sale and fast delivery.